SS316 BALL VALVE (FEMALE X FEMALE) 10000PSI.

Valve Features

- Manufactured from high integrity barstock materials 304L/ SS 316 L.

- Three piece Body Design.

- Choice of panel mounting model (optional) for ease in- stallation.

- Low torque and smooth 90o operation.

- Bi-directional floating ball design which ensure leak- proof shut-off on pressure or vacuum.

- Anti-blow out stem with shoulder design (internally Loaded) for safety and seal integrity.

- Temperature rating -20oC to 250oC.

- Pressure rating up to 6000 PSI.

- Full material traceability.

- 100% hydrostatically tested.

- Handle indicates open/ close position.

- Available NPT or BSPP thread end connection.

SS316 BALL VALVE (FEMALE X FEMALE) 6000PSI.

Valve Features

- Manufactured from high integrity barstock material SS 304L/ 316

- Three piece Body

- Single nut panel mounting facility for ease

- Low torque and smooth 90o

- Bi-directional floating ball design which ensure leak- proof shut-off on pressure or vacuum.

- Anti-blow out stem with shoulder design (internally

- Loaded) for safety and seal integrity.

- Temperature rating -50oC to

- Pressure rating up to 3000

- Full material

- 100% hydrostatically

- Handle indicates open/ close

- Available Inch or Metric Tube end

SS316 BALL VALVE (TUBE X TUBE) 3000PSI.

FEATURES

Maximum working pressure:

3000 psi (206 bar) at 38°C

Working temperature:

From -54°C to 180°C with PEEK Packing.

A short handle gives quarter turn rust-free operation.

Valves with PTEF seats are supplied with short handles.

A robust pin is to create a positive stop.

The stem +with shoulder provides blowout proof design to maintain seal integrity at all pressure.

Optional sour gas service conforms to NACE Mr0175.

Ball valves are hydrostatic tested at the full rated pressure and low pressure pneumatic at 70 psi.

100% factory test

SS316 BALL VALVE ROUND BODY (FEMALE X FEMALE) 3000PSI.

FEATURES

• Manufactured from high integrity barstock material SS

304L/SS 316 L.

• Two piece and flexible Body Design.

• Low torque and smooth 90o operation.

• Bi-directional floating ball design which ensure leakproof

shut-off on pressure or vacuum.

• Anti-blow out stem with shoulder design (internally

Loaded) for safety and seal integrity

• Temperature rating -50oC to 230oC.

• Pressure rating up to 3000 PSI.

• Full material traceability.

• 100% hydrostatically tested.

• Handle indicates open/ close position.

• Available NPT or BSPP thread end connection.

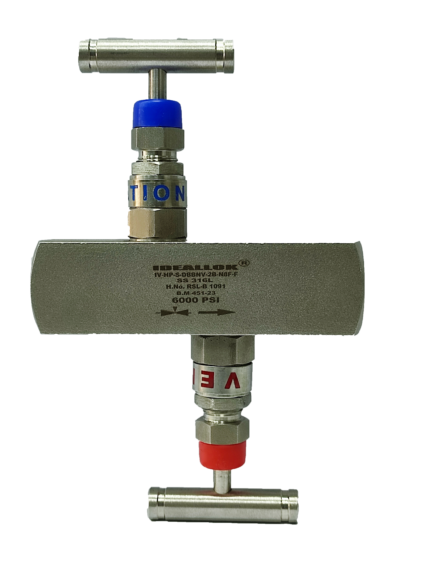

SS316 BLOCK & BLEED 2 WAY (FEMALE X FEMALE) 10000PSI. & 6000PSI.

Valve Features

- Maximum working pressure 6000PSI at 100oF( 38oC)

- Working Temperature -65oF(-54oC) to 356oF(180oC)

- Non rotating stem design reduce galling and provide ex- cellent seal on seat

- Stem threads are rolled and lubricated to prevent galling and reduces operating torque

- PTFE packing is standard and for higher temperature ap- plication Graphoil is used

- Gland packing can be adjusted to extend the valve

- Back seat stop stem for blowout prevention

- Bonnet lock pin prevents accidental removal while in op- eration

- Valve designed for mount pressure gauges, pressure transmitters etc. and save cost, space and weight sig- nificantly

- Low Torque operating T bar Handle

- 00% Quality Tested

- Full Material Traceability

- Hydro test performed @ of 5 times of working pressure

- Protective Dust cap provided to prevent contaminants entry

- Sour gas service conforms to NACE MR0175 is optional

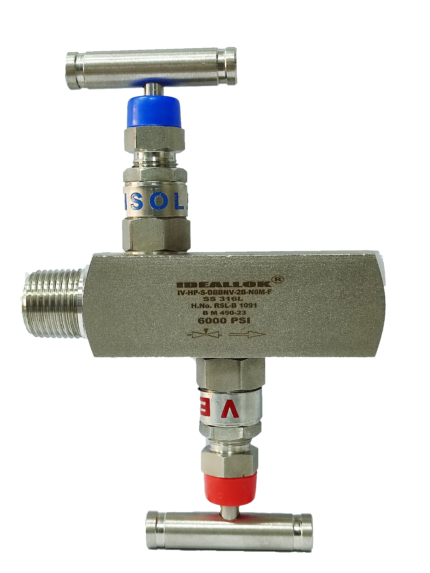

SS316 BLOCK & BLEED 2 WAY (MALE X FEMALE) 10000PSI. & 6000PSI.

Valve Features

- Maximum working pressure 6000PSI at 100oF( 38oC)

- Working Temperature -65oF(-54oC) to 356oF(180oC)

- Non rotating stem design reduce galling and provide ex- cellent seal on seat

- Stem threads are rolled and lubricated to prevent galling and reduces operating torque

- PTFE packing is standard and for higher temperature ap- plication Graphoil is used

- Gland packing can be adjusted to extend the valve

- Back seat stop stem for blowout prevention

- Bonnet lock pin prevents accidental removal while in op- eration

- Valve designed for mount pressure gauges, pressure transmitters etc. and save cost, space and weight sig- nificantly

- Low Torque operating T bar Handle

- 00% Quality Tested

- Full Material Traceability

- Hydro test performed @ of 5 times of working pressure

- Protective Dust cap provided to prevent contaminants entry

- Sour gas service conforms to NACE MR0175 is optional

SS316 CHECK VALVE (FEMALE X FEMALE) 10000PSI.

SS316 CHECK VALVE (FEMALE X FEMALE) 3000PSI.

SS316 CHECK VALVE (FEMALE X FEMALE) 6000PSI.

SS316 HIGH PRESSURE BALL VALVE (M X F) 10000PSI.

Valve Features

- Manufactured from high integrity barstock material SS 304L/ SS 316

- Two piece and flexible Body

- Low torque and smooth 90o

- Bi-directional floating ball design which ensure leak- proof shut-off on pressure or vacuum.

- Anti-blow out stem with shoulder design (internally Loaded) for safety and seal

- Temperature rating -50oC to

- Pressure rating up to 10000

- Full material

- 100% hydrostatically

- Handle indicates open/ close

- Available NPT or BSPP thread end

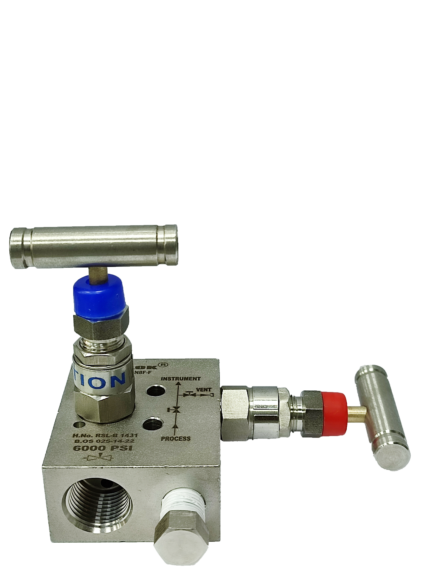

SS316 MANIFOLD 2 WAY R-TYPE (FEMALE X FEMALE) 6000PSI.

Valve Features

- Maximum working pressure 6000PSI at 100oF( 38oC)

- Working Temperature -65oF(-54oC) to 356oF(180oC)

- Non rotating stem design reduce galling and provide ex- cellent seal on seat

- Stem threads are rolled and lubricated to prevent galling and reduces operating torque

- PTFE packing is standard and for higher temperature ap- plication Graphoil is used

- Gland packing can be adjusted to extend the valve

- Back seat stop stem for blowout prevention

- Bonnet lock pin prevents accidental removal while in op- eration

- Low Torque operating T bar Handle

- 100% Quality Tested

- Full Material Traceability

- Hydro test performed @ of 5 times of working pressure

- Protective Dust cap provided to prevent contaminants entry

- Sour gas service conforms to NACE MR0175 is optional

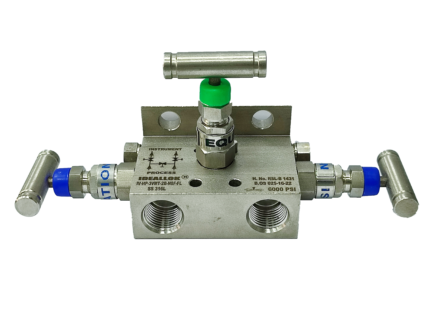

SS316 MANIFOLD 3 WAY T-TYPE (FLANGE X FEMALE X FEMALE)

Valve Features

- Maximum working pressure 6000PSI at 100oF( 38oC)

- Working Temperature -65oF(-54oC) to 356oF(180oC)

- Non rotating stem design reduce galling and provide ex- cellent seal on seat

- Stem threads are rolled and lubricated to prevent galling and reduces operating torque

- PTFE packing is standard and for higher temperature ap- plication Graphoil is used

- Gland packing can be adjusted to extend the valve

- Back seat stop stem for blowout prevention

- Bonnet lock pin prevents accidental removal while in op- eration

- Low Torque operating T bar Handle

- 100% Quality Tested

- Full Material Traceability

- Hydro test performed @ of 5 times of working pressure

- Protective Dust cap provided to prevent contaminants entry

- Sour gas service conforms to NACE MR0175 is optional